drvo

Ova internetska stranica koristi kolačiće kako bi se osiguralo

da dobijete najbolje iskustvo na našoj web stranici.

Više informacija

da dobijete najbolje iskustvo na našoj web stranici.

Više informacija

Sektor

Ostali brandovi

|

balestrini fox md |

|

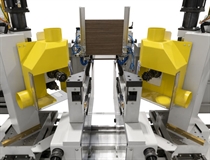

Stroj za šlicanje i urezivanje s dvije CNC glavne jedinice namijenjen za izvođenje urezanih spojeva pod 45° za proizvodnju štokova i vrata. Podešavanje stroja kontrolira se numeričkom kontrolom. Zahvaljujući prilagodbi NC stroja i automatskom dodavaču, ovaj stroj postiže neusporedivu produktivnost. Novo Maestro sučelje Human-Machine omogućuje jednostavno programiranje i slanje makronaredbi u stroj. |

Prednosti

CNC POZICIONIRANJE GLAVNIH JEDINICA

Desna i lijeva jedinica sastavljene od jedinice za šlicanje i, kao opcija, jedinice za bušenje/urezivanje, mogu se NC postaviti pod različitim kutovima, omogućujući izvođenje operacija obrade čak i pod negativnim kutom.

Desna i lijeva jedinica sastavljene od jedinice za šlicanje i, kao opcija, jedinice za bušenje/urezivanje, mogu se NC postaviti pod različitim kutovima, omogućujući izvođenje operacija obrade čak i pod negativnim kutom.

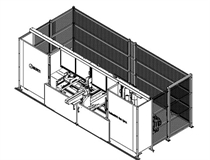

UTOVARNA STANICA S AUTOMATSKIM DODAVAČOM

Na prednjoj strani stroja postavljena je utovarna stanica opremljena automatskim ubacivačem koji jamči vrijeme utovara i istovara za manje od 3".

Na prednjoj strani stroja postavljena je utovarna stanica opremljena automatskim ubacivačem koji jamči vrijeme utovara i istovara za manje od 3".

SIGURNOST I ERGONOMIJA

Zaštitno kućište s ručnim otvaranjem/zatvaranjem osigurava potpunu sigurnost tijekom radnih faza i maksimalnu ergonomiju pri ulasku u stroj radi postavljanja i održavanja.

Zaštitno kućište s ručnim otvaranjem/zatvaranjem osigurava potpunu sigurnost tijekom radnih faza i maksimalnu ergonomiju pri ulasku u stroj radi postavljanja i održavanja.

MASNO DRVO ALI I MDF

Zahvaljujući makroima prisutnim u Human-Machine Interface Maestro aktivnom joint, moguće je obraditi izratke od punog drva, ali i od MDF-a obloženog melaminskim papirom.

Zahvaljujući makroima prisutnim u Human-Machine Interface Maestro aktivnom joint, moguće je obraditi izratke od punog drva, ali i od MDF-a obloženog melaminskim papirom.

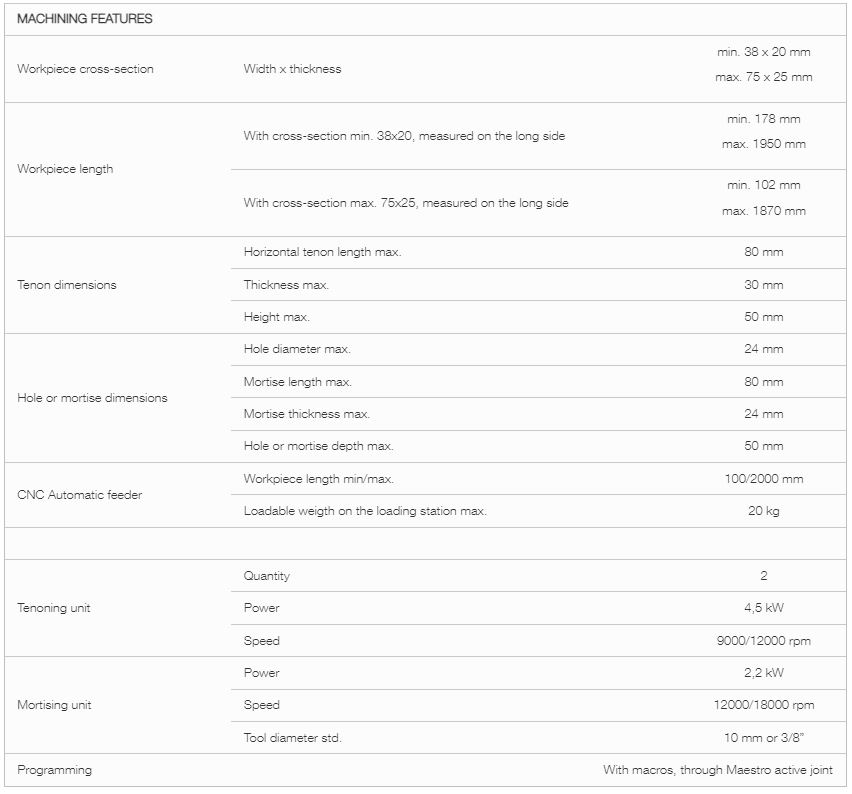

Tehnički podaci

Media

Dokumentacija